Information

Efficient Mini Heater for Heating Resin

When working with resin, achieving the perfect cure is essential. Whether you are a seasoned resin artist or a hobbyist, using a mini heater can greatly enhance the quality of your resin projects. This guide will help you understand the importance of a mini heater for heating resin, what features to look for, and some top recommendations.

Introduction

Resin projects require a controlled environment to cure properly. One common issue many resin artists face is bubbles, which can ruin the clarity and smooth finish of the resin. Using a mini heater for heating resin can help eliminate these bubbles and ensure an even, thorough cure. In this guide, we will explore why a mini heater is a crucial tool for resin artists, the key features to consider when purchasing one, and some top models available on the market.

Why You Need a Mini Heater for Heating Resin

A mini heater is essential for resin projects because it provides consistent and controlled heat, which is vital for curing resin properly. The heat helps to reduce bubbles, ensuring a smooth and professional finish. Additionally, a mini heater can accelerate the curing process, saving you time and allowing you to complete projects more efficiently.

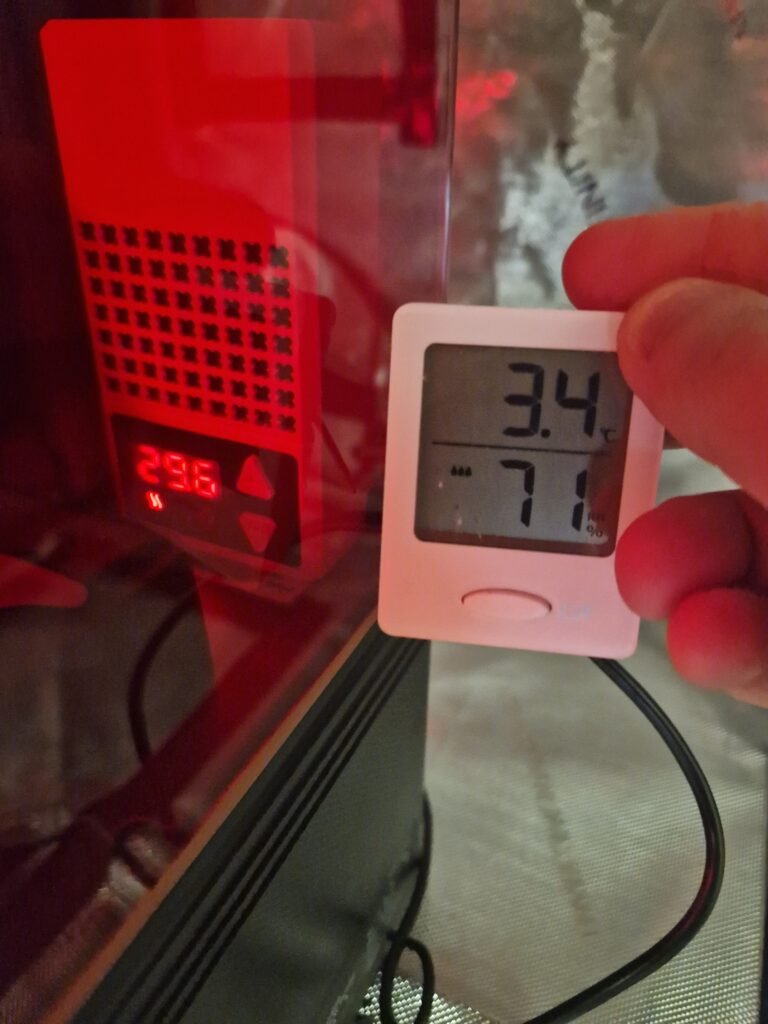

Temperature Control

One of the most important features to look for in a mini heater for heating resin is temperature control. Resin requires a specific temperature range to cure correctly. Too much heat can cause the resin to cure too quickly, leading to cracks or uneven surfaces, while too little heat can result in a sticky, uncured surface. Look for a mini heater with adjustable temperature settings so you can maintain the ideal temperature for your resin projects.

Size and Portability

Another key consideration is the size and portability of the heater. Resin projects can vary in size, so it’s important to choose a mini heater that can accommodate different project sizes. A compact and lightweight design is preferable as it allows for easy handling and storage. Additionally, a portable heater can be used in different locations, making it a versatile tool for your resin projects.

Heat Distribution

Even heat distribution is crucial for resin curing. Uneven heat can lead to inconsistent curing, resulting in defects in your resin pieces. When selecting a mini heater, ensure that it provides even heat distribution to avoid these issues. Some heaters come with built-in fans or other mechanisms to ensure the heat is evenly spread across the entire surface of the resin.

Safety Features

Safety should always be a top priority when working with any heating device. Look for mini heaters that come with safety features such as overheat protection, automatic shut-off, and cool-touch exteriors. These features not only protect you from burns and other injuries but also ensure that your resin projects are completed safely.

Energy Efficiency

Energy efficiency is another important factor to consider. An energy-efficient mini heater will consume less electricity, which can save you money in the long run. Additionally, energy-efficient heaters are often better for the environment, reducing your overall carbon footprint.

Durability

Durability is crucial, especially if you plan to use the mini heater frequently. Choose a model made from high-quality materials that can withstand regular use. Reading customer reviews and checking product specifications can give you an idea of the heater’s durability.

Top Picks for Mini Heaters

Model A: Best Overall

- Pros: Excellent temperature control, durable build, efficient energy consumption

- Cons: Slightly higher price point

- Why We Love It: Model A offers the best balance of performance, safety, and durability. Its precise temperature control ensures perfect resin curing every time.

Model B: Best Budget Option

- Pros: Affordable, compact design, good heat distribution

- Cons: Limited temperature settings

- Why We Love It: For those on a budget, Model B provides reliable performance without breaking the bank. Its compact design makes it easy to store and transport.

Model C: Best for Large Projects

- Pros: Large heating surface, even heat distribution, robust safety features

- Cons: Bulky size

- Why We Love It: Model C is ideal for larger resin projects. Its extensive heating surface and consistent heat distribution ensure that even the biggest projects cure perfectly.

Additional Tips for Using a Mini Heater for Heating Resin

Proper Setup

Ensure that your mini heater is set up in a well-ventilated area. Resin fumes can be hazardous, so it’s important to work in a space with good air circulation. Additionally, make sure that the heater is placed on a stable, heat-resistant surface to prevent accidents.

Monitoring the Curing Process

Keep an eye on your resin project as it cures. Even with a mini heater, it’s important to monitor the temperature and make adjustments as needed. Some resins may require different curing times and temperatures, so always refer to the manufacturer’s instructions.

Using a Fermentation Belt

In some cases, a fermentation belt can be used in conjunction with a mini heater for heating resin. Fermentation belts are designed to wrap around containers, providing consistent and controlled heat. This can be particularly useful for larger resin projects or when working in colder environments. Just like mini heaters, fermentation belts should have adjustable temperature settings and safety features.

Conclusion

Choosing the right mini heater for heating resin can make a significant difference in the quality of your resin projects. By considering factors such as temperature control, size, heat distribution, safety features, energy efficiency, and durability, you can find the perfect heater for your needs. Whether you are a beginner or an experienced resin artist, investing in a high-quality mini heater will help you achieve professional results.

We hope this buyer’s guide has been helpful. If you have any questions or experiences to share about using a mini heater for heating resin, please leave a comment below. We’d love to hear from you!

Pingback: Resin Printing – 3D Printing Troubleshooting and Why Heat Matters in Resin Printing – Stranden Fabrications